Rubröder BC-Systems

Printed Board Cleaning System

Function:

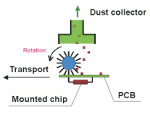

We are not using a sticky reel like other systems. The special ESD safe brush of all the BC-Series systems rotates and oscillates at the same time and therefor guarantees a maximum of cleaning efficiancy.

A vacuum suction system above the brush takes the dust away and runs it to a particle filter. Option available as ionizing air knife bar to neutralise electrical charges.

New added model BC-250A

This model uses the brush system for cleaning of the bottomside of the PCB and a new system with a special made Air Knife on the top side.

BC-250B cleans with brush from the top side- available also as a weider model BC-460B

BC-250D cleans with brushes from both top/bottomside - available also as a weider model BC-460D

During production of electronic boards, there are many sources of particles which can contaminate the surface of PCBs. If these particles are located on solder pads during the paste printing process, it can cause problems during soldering of the boards or can reduce the quality of a solder joint.

Our Board Cleaning Systems BC-250B and BC-460B are designed to overcome these problems.

Areas of use & advantages:

To remove particles from the baord surface prior to paste printing

To increase line efficiancy

Easy to install and use

SMEMA interface

Low maintenance cost and work

smartTec will help you find the right products for your specific needs.